Frequently Asked Questions

What is the Correct Adjustment Setting for the C-4 Bands?

In order to get the best performance from your C-4, it is important to adjust your bands properly.

The Ford C-4 has two bands, a Front or Intermediate Band and a Rear Band.

The front band can have one of two different threaded adjuster studs, coarse or fine thread.

The Coarse thread should be adjusted by tightening the nut to eliminate play, then back it out 1 and a half turns.

The Fine thread stud should be tightened to remove play, then backed out 2 and a half times.

The rear band gets adjusted by tightening to remove slack then backing out the nut 2 and a half times.

Why should I have my transmission and/or converter freshened up by DYNAMIC Racing Transmissions?

Nobody knows your genuine DYNAMIC/TCT equipment better! A good deal of a DYNAMIC Racing Transmission and TCT Converter’s success is the result of our specially designed components and the exacting methods utilized in their assembly.

When exposed to the rigors of competition, a well designed and custom built race component will always outlast a stock component. DYNAMICS’ correct assembly of all components is paramount to a unit’s success and long life. Not to say that there are no other competent builders out there, it’s just that for a DYNAMIC Racing Transmission to operate at peak performance (for the original owner as well as a second hand buyer) it makes sense to have the original designer and builder do any required maintenance. Keeping our overhaul work affordable makes it that much easier to take advantage of.

Each transmission is dynotested after assembly to ensure its perfect operation. Overall line pressure, at idle as well as at shift points, are monitored and adjusted as necessary. Shift precision, trans-brake action (where applicable) and overall seal quality (including torque values on SFI Approved Bellhousings) and noise levels are all checked. It’s this kind of attention to detail that assures that every DYNAMIC transmission is up to par. DYNAMIC/TCT equipment upon purchase, or after overhaul- All perform at their peak.

As converter and transmission health often go hand in hand, it’s always a good idea to have your converter checked out with each transmission freshen-up.

If after a converter is inspected it's found to be in good "health," it is cleaned and the hub is polished for a minimum service charge. If there is evidence of a problem, or the owner desires a stall change, or just wants a freshen- up while everything is out of the car- the converter will be cut open.

A converter freshen-up consists of cleaning, a full inspection– including clearances and condition of fins, replacing all bearings and roller and spring assembly, hub polishing, re-closing, pressure check, and electronically balancing to within 1 gram of weight.

Please call for pricing information.

What are the differences in the levels of transmission that you offer?

We offer a complete line of Street/Strip, Basic Comp units, Upgraded Comp for higher HP, and various transbrake equipped units, including the Mighty Mite, M2 and the full line of Pro-Tree 2 Glides. Also, we offer units for NHRA, which range from Stock Eliminator, Super Stock, and Open Comp transmissions. For Mustangs, we have basic street/strip parts, all the way up to Pro 5.0 type transmissions.

We also offer: Vasco Jet output shafts, Vasco Jet input shafts, Low ratio gear sets, new carriers, rollerized planetaries, Alto High Performance Red Eagle frictions, and Kolene Steels, Kevlar bands, and Teflon sealing rings.

All of these parts are either installed originally on our transmissions, or are options that the customer can choose at the time of purchase.

It is Dynamic's custom approach to each sale that allows the customer to get the most of what he needs at the best price. They have also made it a point to warranty entry-level transmissions the same as the more expensive ones.

My new Valve Body from you doesn't shift correctly. What could cause this?

All Dynamic Racing Transmissions built valve bodies are dyno tested in-house before being shipped.

It is the customer's responsibility to follow the included directions and provide the detent roller and filter.

What kind of difference would a racer see by purchasing something like the Mighty Mite II over having the transmission re-built by his local shop?

- Our quality of merchandise, where we select cores, which are all hand picked.

- Our durability, our guarantee, and most of all, the consistency that our parts offer.

- After all, racing and high performance in general is all we do, and all we have done for many years.

- When you order a Dynamic Racing Transmission it is disassembled and rebuilt by one technician. We have no assembly line, or mass produced units.

- Every unit built in our shop is treated as a custom order and built as one.

- The final step is always a run in on our Dyno to check pressures, shift quality and no leaks.

How Does A Transbrake Work?

Transbrakes were designed to allow racers the ability to launch their vehicles at a consistant rpm without pushing through the staging beams. Footbraking a high stall vehicle can be a handful, often overpowering the brakes and causing the redlight to trip.

There are two basic types of trans brakes, internal solenoid and external solenoid. This is the difference of where the energizing solenoid is mounted on the transmission.

The solenoid is activated by sending a 12 volt charge from a remotely connected button to the coil of the solenoid. This in turn forces the plunger of the solenoid forward which pushes the modulator valve in the case, applying the reverse circuit.

The vehicle must be in first gear for the transbrake to lock.

Once set, the driver can raise the engine rpm's to the pre determined level and prepare for the Tree countdown.

On the last yellow, he releases the button thus deactivating the solenoid and the reverse circuit.

There are several styles of brakes available from Dynamic Racing Transmissions. For the C4 we offer the Forward Manual Brake, which keeps the stock shift pattern combined with the transbrake action. The Bracket Brake which is a reverse manual pattern P R N 1 2 3 and it is designed for Full Tree racers. The Pro Tree Brake is our quickest brake and also is reverse pattern but requires solenoid activation to engage Reverse to back up. It is designed for the .400 Pro Tree racers.

All Dynamic Brakes utilize the external solenoid for easy maintenance.

We offer brakes for most American transmissions, as well are manual and street/strip valve bodies.

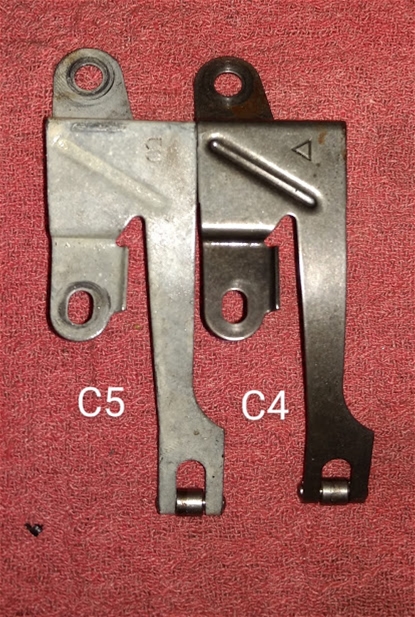

Which C-4 Valve Body can be used as a core?

The Ford C-4 valve body has gone through a number of modifications over the years.

But there is only one style that can be used as a core when building a performance C-4 valve body or trans brake.

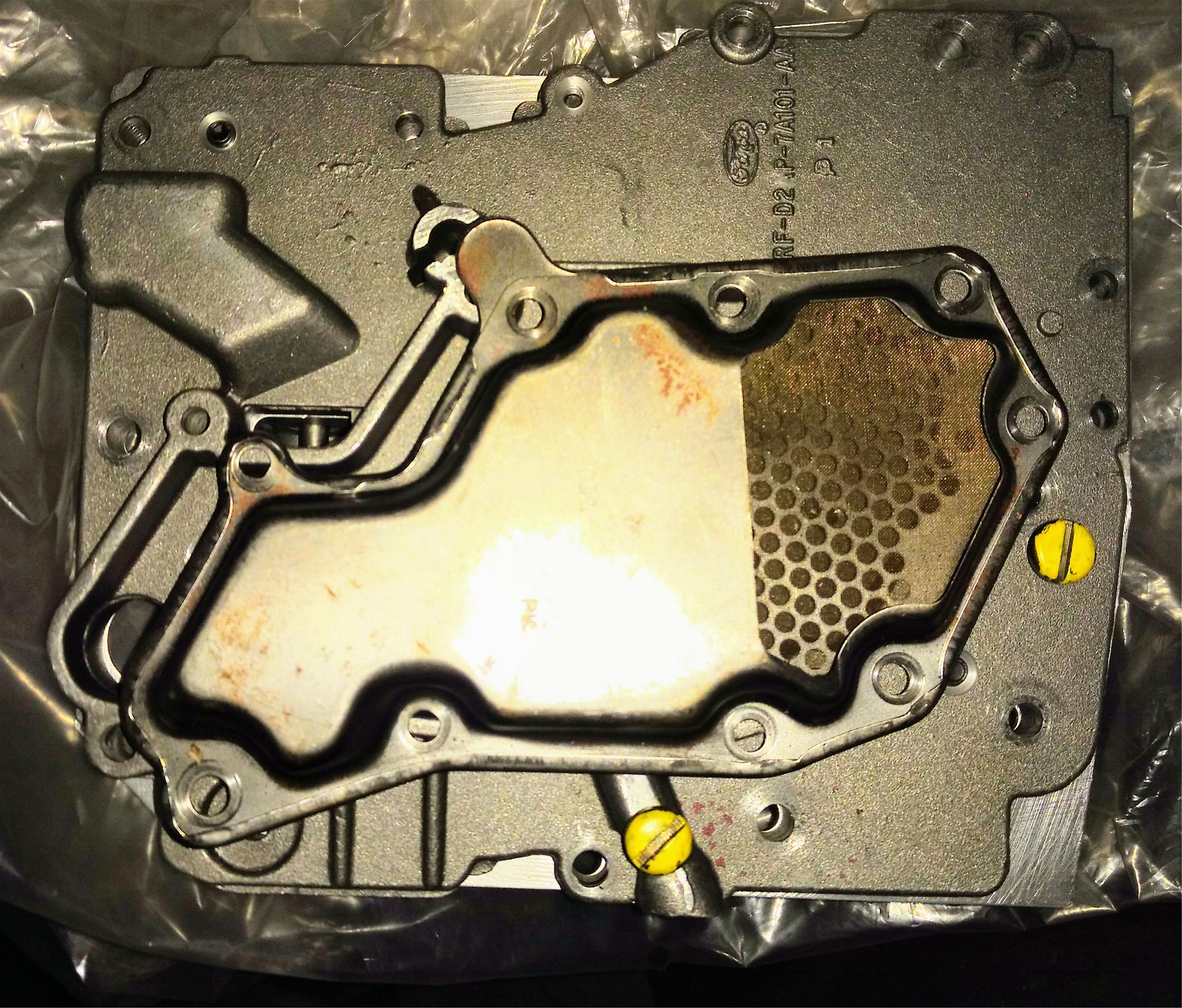

The 1970 and up C-4 valve body can be identified easily by the location of the filter relief location.

If the filter has an integral tab that covers the filter relief valve, as shown in the picture below, it is the correct unit.

If the filter relief valve is exposed and has the spring held in place with a pin, it is the wrong unit.

Wrong Core

Correct Core

What if time limits/shipping considerations make it unfeasible to send in my equipment during the season?

Let me emphasize the importance of in-house DYNAMIC overhauls to keep your DYNAMIC/TCT equipment all genuine.

However, if this just isn’t a possibility, your best bet is to call us and get the full overhaul kit for your particular unit. You, or your builder, will be getting the same exact parts that are used here when doing a full overhaul- whether it be a Mighty Mite C4, a Pro-Tree 2 Glide, or even a maxed out T400.

Technical assistance is available to our customers via E-mail or phone.

Do-it-yourselfers also have the option of upgrading.

Components are available to upgrade a Comp C4 to a Mighty Mite, or a Mighty Mite to the M2 model and beyond. Chevy and Mopar owners have the same opportunity open to them.

No component sold by DYNAMIC is all flash. Our parts are designed to give added durability and better performance.

Where would you recommend a customer to switch to a Powerglide from a C4? And what are the advantages to the Powerglide?

It all depends on the weight of the car, which class it will be run in, and the horsepower level that the car has attained.

Some classes will only allow for a C4 transmission, and on the other hand, some cars are in classes where a Powerglide or Turbo 400 are really the only choice due to durability or weight issues.

It all really depends on the use of the car, and which class it will run in.

The hp limit on a C4 Mighty Mite M2 is around 1200HP. Beyond that, we recommend a 400 or glide.

What is the correct way to check transmission fluid level?

The most accurate way is to have the car on a level surface with the engine running and the car in park.

Have someone sit in the driver's seat with their foot on the brake pedal.

With the engine at operating temperature and idling, pull out the dipstick and wipe it clean. Re-install the stick for a moment then pull it out again and check the level on the stick.

If it needs more fluid, add it in small amounts making sure not to overfill.

On a race car we recommend the Fluid level should be 1/4" above the pan rail. Place your dipstick along the outside of the tube and mark it 1/4" above the rail. Use that as hot full mark.

If I purchase your transbrake solenoid for my tranny, will that be all I need to have a transbrake tranny?

In one word, No.

The solenoid that we offer is a replacement for our current solenoid equipped transbrakes in the event it is damaged by voltage spikes or excessive holding down of the button.

To upgrade a transmission to a transbrake unit you must purchase the transbrake valvebody kit which includes the solenoid.

It should be noted that by installing the valvebody kit to have transbrake functions will put additional stress on internal components. This is why we highly recommend you start with a race prepped transmission, like the Dynamic units, to ensure proper function and reliability.

We have a C4 case with a screw in vacuum modulator. Can I run an external transbrake solenoid?

Yes you can. However, the case needs to modified in the area where the vacuum modulator screws in.

You will need to drill out the case threads for the modulator using a 37/64" drill to the depth of 3/4".

Next you will need to tap the drilled hole with a 5/8"-18 tap.

Be sure to remove all drill residue before installing the brake valve and spring that comes with your new transbrake valve body.

Apply a thin coat of rtv sealer to the washer on the solenoid and thread into place.

What temperature should my competition or street & strip automatic run at?

Generally, temperature readings of 180 to 210 are ideal- with 210 being hit under harsh conditions, but 180 to 190 being the norm. We’ve seen many cars that will not even reach 180 while racing. To consistently run in this temperature range, it is important that the maximum amount of the correct fluid be run with the use of a cooler and the added insurance of an electric fan. Of course, to take advantage of this knowledge and enjoy the maximum protection for your DYNAMIC transmission, it is assumed that a temperature gauge will be used to monitor the unit.

What about TCT's converters differs from the competition?

TCT's one-on-one customer service, along with building each converter combination specific for each customer's vehicle is what makes us different.

Even our Bottle Rocket Converters are built to order. No off the shelf, mass produced, one size fits all units.

By doing this, day in and day out, we assure our customers of the latest design changes as far as performance, durability, and customer satisfaction.

For fastest service and pricing fill out our Converter Order Form and click submit.

One of our techs will contact you with a recommendation and price.

What is the most important thing in determining a particular size converter?

Determining the proper size converter to use in each application depends on a lot of variables and driving preferences.

Generally, vehicle weight, engine size and torque output, tire size, gear ratio and whether its for street/strip, or all out race are the main factors we use to construct each individual converter.

Those factors are all determined in our individual, one-on-one selection process.

Another measurement that is typically misunderstood is "stall speed". Stall speed is determined by converter size and volume. The smaller the converter, the more stall speed will be realized. As the size goes up from an 8 inch diameter to an 11 inch diameter, the stall speed lowers, and the efficiency rises. The larger the converter, the more fluid it will hold, and the volumetric efficiency will increase.

What sets your converters apart from other companies?

There are several reasons that TCT converters differ from other companies.

Since converter selection is different for each and every customer, it is our personalized service.

At TCT, the converter is selected by the converter technician, who has his hands on each facet of the assembly operation. This is vital to the customer, whose car and combination needs a properly selected converter to assure proper performance.

It can't be said enough, one size converter does NOT fit all. TCT is on the leading edge of converter technology, whether it is being installed in a 6-second Pro car, or your daily driver.

Every TCT converter is custom designed to fit your individual needs, and we rely on our years of experience to help determine what will work best for each combination.

Another factor that sets us apart is component selection. Constant research and development, not only on converter performance, but also on individual components, helps us to pick the best parts for each customer.

Stator and Sprag design and development are critical to the proper performance of your torque converter.

Our assembly technique is another area which is critical to performance, and something that cannot be compromised. Concentrating on strength and durability has paid huge dividends to our customers, along with working with some of the racing industry's most successful engine builders. Their input on changes in engine technology has been huge in our converter development. We also work with many, many racers in the NMRA, Fun Ford, NHRA, and IHRA circuits.

Why don't you rate your converters by stall speed?

When stall speed converters first came on the market they were rated by what effective rpm it took to lock up the converter by standing on the brakes and flooring the accelerator.

This was by no means scientific or real world.

Today, we have come to learn that stall speed is determined by the torque output of the engine. You can take a 10" converter that stalls at 3200 rpm on a small block and put it behind a big block and have it stall 3800 rpm.

The amount of torque applied to the converter changes the slip rpm and the lockup. This is why it is so critical to fill out the converter order form with as much info as you can. If you know the hp and torque of your engine you are able to get a more accurate stall speed setting.

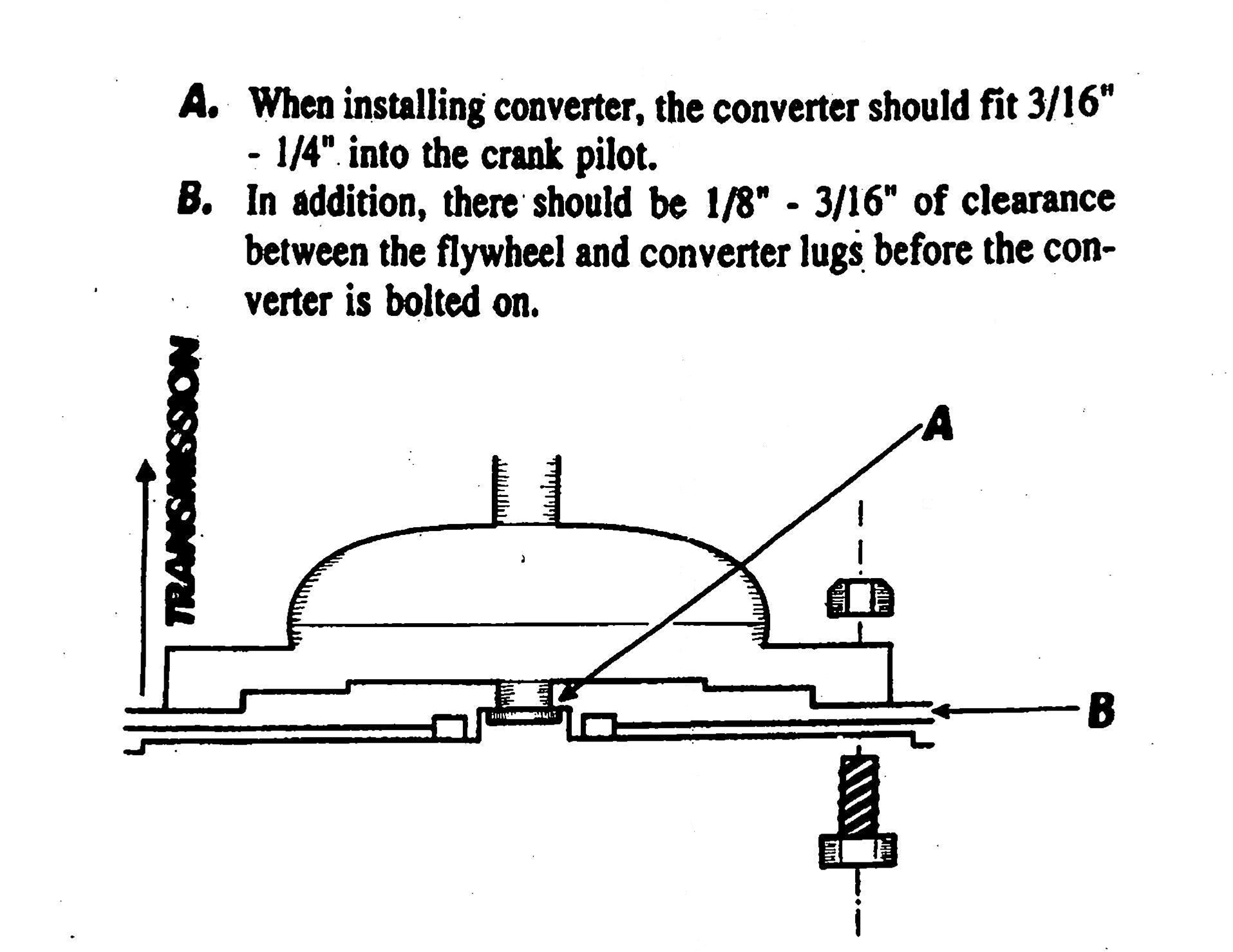

What is the correct spacing dimension between the Converter pads and the flexplate on a Ford C-4 transmission?

The Dynamic Racing Transmissions Ford C-4 transmission and converter packages are designed to have a 1/8" -3/16" gap between the flexplate and the converter mounting pads when the converter is fully seated in the transmission.

If you have zero gap, you need to add a blockplate for your specific size flexplate to attain the proper clearance.

If the gap is beyond the recommended spec, you can add Grade 8 washers between the converter pads and the flexplate to make it work.

What should i use to lubricate my parts during assembly?

Transmission assembly grease.

Never use axle or conventional grease as it will not dissolve into the fluid and plug passages to the ruin of your transmission. Choose something tacky, which will allow you to stick parts together.

Petroleum Jelly is a decent alternative.

Store your assembly lube in the fridge to increase the tackiness for loading those pesky needle bearings. Your assembly grease will melt into the transmission fluid upon first operation of your fresh transmission.

What gear should I start my burnout in?

With the exception of the 727 and 904 transmissions, the burnout procedure should be started in 1st gear.

Once tires are spinning, 2nd should be pulled ASAP.

When the tires are smoking- and before the engine RPM’s can be pulled down, back out of the gas.

How should I check for correct driveshaft length?

With the yoke pushed all the way into the end of the transmission, you should have to pull it back from between ¾” to 1 & ¼” to bolt up the universal.

If the distance is too short, the yoke will bottom out.

If the distance is too great, you will experience a vibration while driving.

What is the best way to ship a C4 transmission to Dynamic?

We recommend that you purchase a 120 quart cooler, similar to the one pictured below.

Drain the unit of all fluid and remove the bellhousing as well as any shifter linkage, transmission mounts, dip sticks or special fittings and shields.

Put packing material all around the unit to prevent movement inside the cooler.

Put your name and contact info in a plastic bag inside the cooler and secure the lid.

We recommend sealing the lid perimeter with duct tape and then securing the cooler closed with a ratchet strap around it.

We suggest going through www.pirateship.com to get the best shipping price.

Bring it to UPS or Fedex and ship it to us:

Dynamic Racing Transmissions

104-5 Enterprise Drive

Unit 1

North Branford CT 06471.

We will arrange shipment back to you using your cooler when the build is complete.